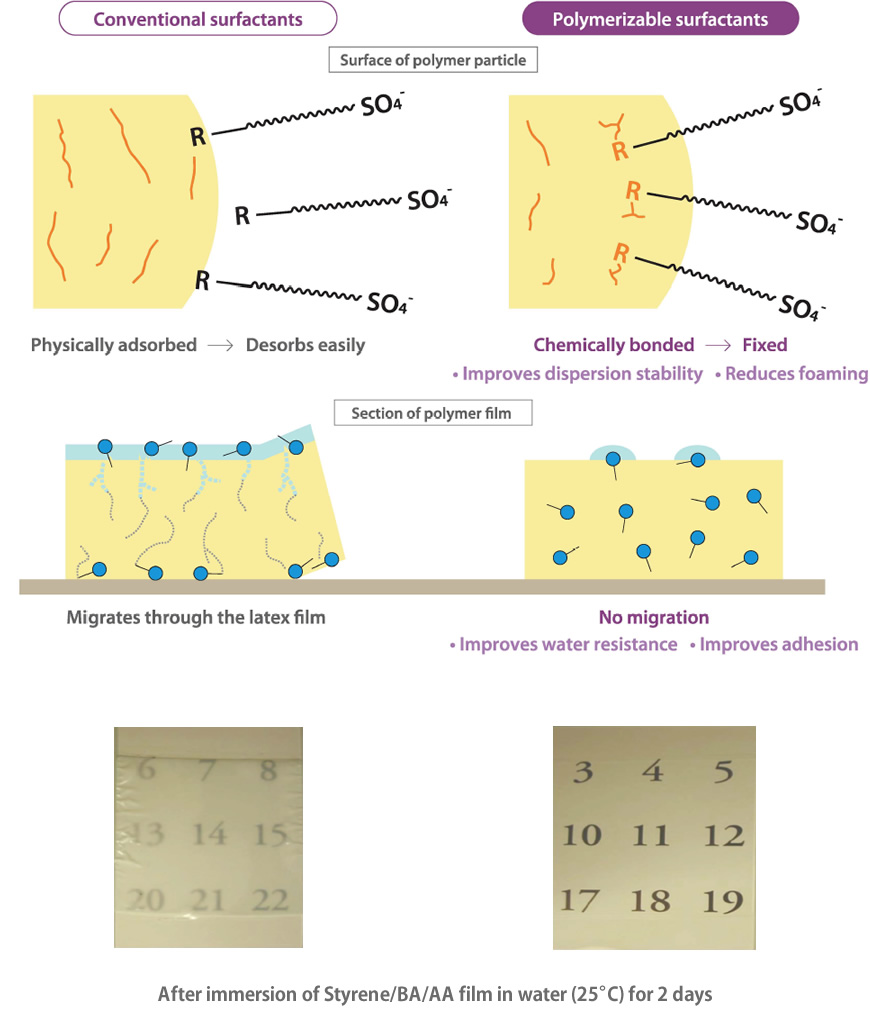

Polymerizable surfactant, HITENOL series was introduced to the industry in the 1980s. Polymerizable surfactants, also known as reactive surfactants bear reactive group that undergoes radical polymerization. They act in emulsion polymerization process both as emulsifiers and as functional monomers. They copolymerize with various monomers and increases the mechanical, chemical and freeze thaw stability of the latex, reduces foaming of the latex, and improves water resistance of the polymer film.

Benefits

- (1)Low Foaming and Fast Defoaming of Latex

- (2)Enhanced Mechanical and Chemical Stability of Latex

- (3)Improved Water Resistance of Polymer Film

- (4)Increased Adhesion of Polymer Film

Comparison of HITENOL grades

| Grade | Ionic Form | Applications | Specific Recommendations by Polymer |

|---|---|---|---|

| HITENOL AR series | Anionic, Ether sulfate | ・ Decorative coatings & paints ・ Industrial coatings ・ Adhesive & sealants |

・ Pure acrylic ・ Styrene acrylics |

| HITENOL KH series | Anionic, Ether sulfate | ・ Decorative coatings & paints ・ Industrial coatings ・ Adhesive & sealants |

・ Pure acrylic ・ Styrene acrylics ・ Vinyl acetate copolymer |

Function of HITENOL in Emulsion Polymerization

Polymerizable surfactant HITENOL bears a carbon-carbon double bond that undergoes radical polymerization. During the initial stage through the middle stage of emulsion polymerization, HITENOL acts just as the same as conventional surfactants to stabilize the polymerization process. In the latter stage, HITENOL copolymerizes with the growing polymer and gets bonded to the surface of the polymer particles and creates a protective layer that stabilizes the polymer dispersion.

HITENOL can be used with the same application and condition as conventional surfactants. Furthermore, HITENOL can solve various disadvantages caused by free surfactants that remain in the aqueous phase, as HITENOL chemically bond to the polymer particle’s surface and there are little free surfactants left in the aqueouse phase.